TECNOLAT tanks mod. SRCG, with jacket to circulate ice water, are made with variable capacity from 500 liters up to a maximum of 100.000 liters.

Yogurt

Milk Coolers

Storage Tanks

Cooling tanks

TECNOLAT tanks mod. SRC, with jacket to circulate refrigerating fluid, are made with variable capacity from 500 liters up to a maximum of 30.000 liters.

Centrifugal Units

TECNOLAT commercializes various model of clarifiers, skimmers, and bactofuga for several applications in the dairy industry and food industry.

Degasers

TECNOLAT degasers operate under vacuum or at very low pressures, allowing the removal of air bubbles and any smelling gas, of environmental origin, that could modify the organoleptic characteristics of the product.

Homogenizers

In the realization of complete lines for milk and/or cheese TECNOLAT provides homogenizers for a variety of applications, taking care of sizing and proper use of the machine in the plant.

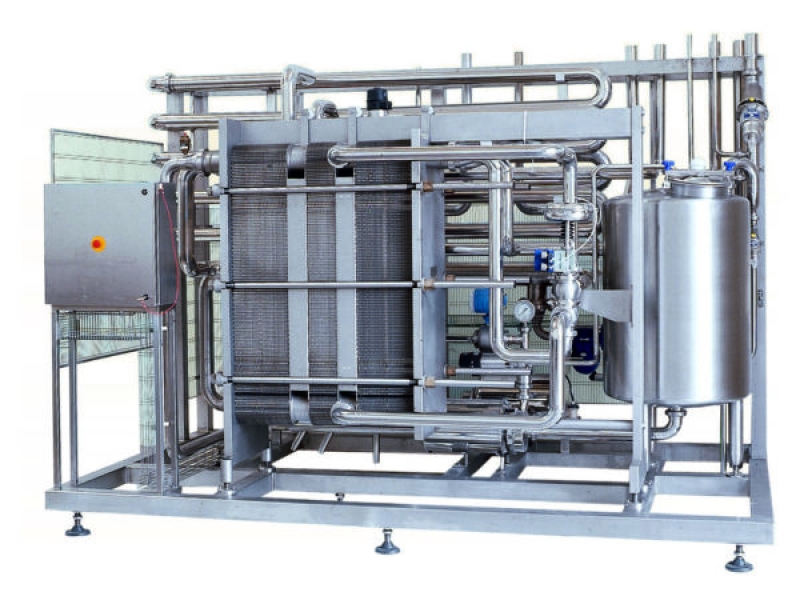

Pasteurizers

TECNOLAT realizes electropneumatic or electronic pasteurizer in compliance with CEE 46/92, 3A standard, or not conforming (marginal uses), according to the customer needs and the product to be treated.

Maturation Tanks

Maturation tanks are insulated tanks, with jacket in order to carry out heating and cooling cycles for the production of the yogurt and of the cream. Equipped with a smoother-mixing group. The group eliminates yogurt lumps and blends fruit and sugar before packaging.